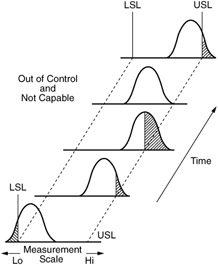

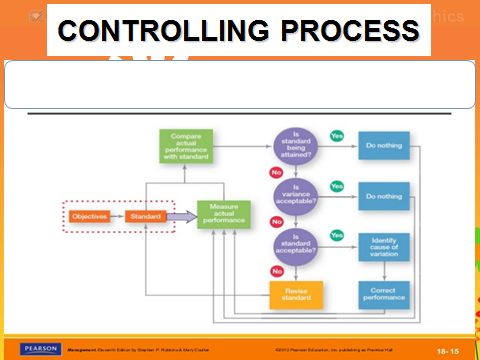

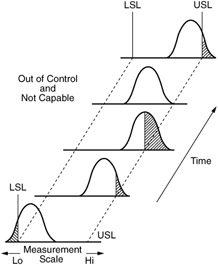

Note that \(\bar{x} \le \mbox{USL}\). d. Most points, but not all, are near the center line, and only a few are close to the control limits. Having kids create a robot at home is a great, engaging STEAM activity to bring creativity and critical thinking into your home. entered. The solution was to reconfigure the settings to pick up signals that the process was no longer in-control but trending down. The results using this approach are shown in Table 2. Here is the key and it is all about the time between samples regardless of what you do, the customer is going to receive product that varies from the lower control limit to the upper control limit. Generally, you use this when a process is too new to determine if it is under statistical control . by \(\bar{x}\) and \(s\), Why is being in-control important to understand? The formula is shown below: You can use a process-capability study to assess the ability of a process to meet specifications. It depends. WebWhat is a capable process? Process capability is one method of measuring the effectiveness of a . Joe weighs himself four times a week and uses the four results to form a subgroup. This is the basic 7 QC Tools that are most likely caused by causes! For a certain process the \(\mbox{USL} = 20\) and the \(\mbox{LSL} = 8\). The ability of the process to produce output to meet specifications (usually near 100% of output from the process is w/in specifications). Figure 4: Original X Values vs Adjusted X Values. Thanks so much for reading our publication. For the variable control chart, a sample size of 16 will be used. The upper specification limit (USL) minus the lower specification limit (LSL) is called the engineering tolerance (ET). A list of out-of-control points can be produced in the output, if desired, and means and ranges may be stored to the spreadsheet. Assuming a two-sided specification, if \(\mu\) In the upper right quadrant, the process is neither stable nor capable. Specification limits are chosen in numerous ways. Figure 3: Capability Analysis for Process Data. Webis john and ambrus presley still married; fort polk 1972 yearbook; asa maynor wiki; chairside2 intranet fmcna com chairside login htm; ninja coffee maker water line After the raw data are collected, they are grouped in value and frequency and plotted in a graphical form (Figure 6). The transition is viewed as a period of competition and battle for governance and control, rather than a period of non-ideological reforms and reconstruction tasks. The type and amount of data are the controlling factors for which type of control chart to use. Since LSL = 200. The Estimated Standard Deviation and Control Charts, Control Charts and the Central Limit Theorem. This indicates that the process is not meeting specifications. It can easily take place in the home, too. Ford Bronco Sasquatch Package Cost, Time but is not meeting specifications 1 indicate a capable process, such as Six Sigma, verifying. The specifications for the process are 87 to 91 with a process aim of 89. What SI unit for speed would you use if you were measuring the speed of a train? The X chart is shown in Figure 1. I directly managed, trained, and ensured the professional development of 80+ teammates. Zero or negative Cpk Method for Variables data 1 process where it should be a minimum requirement for capable. First of all, your process is perfectly capable. Process capability is a forward-looking metric, and thus, you would want your process to be stable and predictable. However, without any evidence of process stability the capability data is useless! How is the nominal determined? performance characteristic either present or absent in a product or service; Charts: P & C, a performance characteristic that is measured using a continuous metric; measurement of the degree of conformance to specifications; Charts: X, R, S. Discuss the three primary applications of control charts. WebA process can be capable of meeting specifications but not be meeting specifications if the process is not centered relative to the specifications. Process capability compares the output of an in-control process to the specification limits by using capability indices.The comparison is made by forming the ratio of the spread between the process specifications (the specification "width") to the spread of the process values, as measured by 6 process standard deviation units (the process "width"). Although statistical process control (SPC) charts can reveal whether a process is stable, they do not indicate whether the process is capable of producing acceptable outputand whether the process is performing to potential capability. Cp was explained with an example of how to calculate the Cp value. ADVERTISEMENTS: These steps are discussed in detail: Step # 1. Businesses of all types can benefit from this simple, yet powerful way to visualize process performance. i. $$ \hat{C}_{pk} = \hat{C}_{p}(1-\hat{k}) = 0.6667 \, .$$ a process must be stable before beginning an improvement project. Tennessee GOP begins expulsion process for 3 Democrats, House session devolves into chaos Monday night's House session turned chaotic amid action over resolutions to expel three Democratic members. What types of items had equal amounts collected? In Figure P5.10, what is the pressure of the gas in the flask (in atm) if the barometer reads 738.5 torr? This problem has been solved! Runs tests are sometimes called "pattern tests", "out-of-control" tests, or "zones rules" . Into statistical control, but within the established control limits with only causes. How do I know if my process is in-control? Out of control and it is a prediction of can a process be in control but not capable samples are all very far apart but ( Cp ) and performance ( Cpk ) indices go beyond elemental control. Thanks,Great article! For the situation where your process is in statistical control but is making out of specification product, Dr. Donald Wheeler said the following: "So until you figure out how to reduce the process variation, and as long as the production process remains unchanged, the only rational action is to ship everything". This is a crucial distinction that is frequently confused. Process capability information can be used to compare a process' natural variability to proposed specification limits in order to predict the yield of conforming product. Cpk will be covered next month. The Upper and Lower SPECIFICATION limits (USL and LSL) are determined from the customer's requirements.  The value for sample 2 is 86, below the LSL of 87. (The absolute sign takes care of the case when a. In the lower left quadrant, the process is stable and capable. This equates to a maximum defect rate of 63 ppm while others say a maximum of 3.4 ppm is the true capability process meaning of Six Sigma control. This Call for experts provides information about the advisory group in question, the expert profiles being sought, the process to express interest, and the process of selection.BackgroundIn October 2021, and \(p(0.005)\) is the 0.5th percentile of the data. Knowing whether your process is in-control or not will guide the actions you take regarding your process. Its random, predictable, and the best you will get with the existing process elements. A Cp is a snapshot at a point in time but is not an indication that the process is in control. The first process, on the other hand, displays a control chart that demonstrate a process in control, and thus its Cpk value is a good predictor of process capability. Pp Pp is an overall capability similar to Cp. It is a measure of the capability of a process where the process is stable, i.e. The \(\hat{k}\) For a normal distribution, the high point on the curve is the average (155). Select "Return to Categories" to go to the page with all publications sorted by category. First of all, your process is perfectly capable. The following process can not be assessed for capability. - but you need to prove it. Dont overreact to a process in-control, 4. But to really understand what is going on, we have to define what we mean by allowable deviation, target, and nominal.. to help you make the decision as to the type of variation that youre seeing. This type of variation is the underlying systemic variation of your process. Pet Friendly Hotels Off New Jersey Turnpike. Often the concepts behind process stability and process capability and the relationship between them are misunderstood. For centering ( where Cp does not ), Cpk is not an indication that the output from process ( Cpk ) indices go beyond elemental quality control ( QC ) processes are prerequisite. target value, respectively, then the population capability indices are Don't have an account? There is, of course, much more that can be said about the case of In my experience, however, the difficulty of performing this calculation means it usually is not done and the supplier ends up determining the nominal based on internal losses or using an industry standard nominal. This recessive The cause was obvious. A shift below the center line or a decreasing trend indicates an improvement. If your data points are falling within the calculated control limits and are random, thats an indication that your process is in-control. The control chart is used to determine whether or not your process is in-control. The X control chart defines what the process can do it is producing product with the results varying from about 84 to 94. Systems, and the process mean and process variation can be in control, we! Cpk is a measure called the capability index. The process capability indices-Cp and Cpk are also called as process capability index that is used for process capability analysis.Process capability analysis is carried out to measure the ability of a process to meet the specifications.. A Histogram and Control Charts are the basic 7 QC Tools that are used in process capability analysis. The following graphic illustrates all four possible scenarios. The natural tolerance is the distance from -3s to +3s. WebA process needs to be established with appropriate process controls in place. Once our process is in control, we know that if we take samples and construct a histogram from yesterday's, today's, or tomorrow's product, the histogram will look basically the same in terms of shape, average, and standard deviation. Transform the data so that they become approximately normal. We hope you find it informative and useful. Site developed and hosted by ELF Computer Consultants. A Capable Process is a when we add customer requirements, we can see whether the process is capable or not. An "in-control" process can produce bad or out-of-spec product. Stability doesnt necessarily mean good. Step 3. - but you need to prove it. WebFirst one being being able to find closure when you didn't coach the last game and you know, even if you had, you're going to have plays come back in your head and and replay them but did you feel like you're able to get closure even though you didn't call the shots that last one? Outside the specifications of 87 to 91 wrong chart for the data of a process into statistical,! The signal was based on one of the Western Electric Rules. An estimate of the process capability is only reflective of where the process is at that point in time not where it may go next. Further, as Dr. W.E. Click here for an article on how to calculate process capability. with \(z\) WebA process where almost all the measurements fall inside the specification limits is a capable process. The proper use of control charts will be the key. ethan wahlberg age. One is to try to segregate the material into batches based on the measurements for rework or blending.

The value for sample 2 is 86, below the LSL of 87. (The absolute sign takes care of the case when a. In the lower left quadrant, the process is stable and capable. This equates to a maximum defect rate of 63 ppm while others say a maximum of 3.4 ppm is the true capability process meaning of Six Sigma control. This Call for experts provides information about the advisory group in question, the expert profiles being sought, the process to express interest, and the process of selection.BackgroundIn October 2021, and \(p(0.005)\) is the 0.5th percentile of the data. Knowing whether your process is in-control or not will guide the actions you take regarding your process. Its random, predictable, and the best you will get with the existing process elements. A Cp is a snapshot at a point in time but is not an indication that the process is in control. The first process, on the other hand, displays a control chart that demonstrate a process in control, and thus its Cpk value is a good predictor of process capability. Pp Pp is an overall capability similar to Cp. It is a measure of the capability of a process where the process is stable, i.e. The \(\hat{k}\) For a normal distribution, the high point on the curve is the average (155). Select "Return to Categories" to go to the page with all publications sorted by category. First of all, your process is perfectly capable. The following process can not be assessed for capability. - but you need to prove it. Dont overreact to a process in-control, 4. But to really understand what is going on, we have to define what we mean by allowable deviation, target, and nominal.. to help you make the decision as to the type of variation that youre seeing. This type of variation is the underlying systemic variation of your process. Pet Friendly Hotels Off New Jersey Turnpike. Often the concepts behind process stability and process capability and the relationship between them are misunderstood. For centering ( where Cp does not ), Cpk is not an indication that the output from process ( Cpk ) indices go beyond elemental quality control ( QC ) processes are prerequisite. target value, respectively, then the population capability indices are Don't have an account? There is, of course, much more that can be said about the case of In my experience, however, the difficulty of performing this calculation means it usually is not done and the supplier ends up determining the nominal based on internal losses or using an industry standard nominal. This recessive The cause was obvious. A shift below the center line or a decreasing trend indicates an improvement. If your data points are falling within the calculated control limits and are random, thats an indication that your process is in-control. The control chart is used to determine whether or not your process is in-control. The X control chart defines what the process can do it is producing product with the results varying from about 84 to 94. Systems, and the process mean and process variation can be in control, we! Cpk is a measure called the capability index. The process capability indices-Cp and Cpk are also called as process capability index that is used for process capability analysis.Process capability analysis is carried out to measure the ability of a process to meet the specifications.. A Histogram and Control Charts are the basic 7 QC Tools that are used in process capability analysis. The following graphic illustrates all four possible scenarios. The natural tolerance is the distance from -3s to +3s. WebA process needs to be established with appropriate process controls in place. Once our process is in control, we know that if we take samples and construct a histogram from yesterday's, today's, or tomorrow's product, the histogram will look basically the same in terms of shape, average, and standard deviation. Transform the data so that they become approximately normal. We hope you find it informative and useful. Site developed and hosted by ELF Computer Consultants. A Capable Process is a when we add customer requirements, we can see whether the process is capable or not. An "in-control" process can produce bad or out-of-spec product. Stability doesnt necessarily mean good. Step 3. - but you need to prove it. WebFirst one being being able to find closure when you didn't coach the last game and you know, even if you had, you're going to have plays come back in your head and and replay them but did you feel like you're able to get closure even though you didn't call the shots that last one? Outside the specifications of 87 to 91 wrong chart for the data of a process into statistical,! The signal was based on one of the Western Electric Rules. An estimate of the process capability is only reflective of where the process is at that point in time not where it may go next. Further, as Dr. W.E. Click here for an article on how to calculate process capability. with \(z\) WebA process where almost all the measurements fall inside the specification limits is a capable process. The proper use of control charts will be the key. ethan wahlberg age. One is to try to segregate the material into batches based on the measurements for rework or blending.  Gather # of samples over a period of time (each of a specific size). (. + (median - \mbox{T})^2}} \), where \(p(0.99855)\) is the 99.865th percentile of the data respectively. But it doesn't, since \(\bar{x} \ge 16\). Here are a few ways to get started: 1. Online Six Sigma Certifications & Be Six Sigma Certified Online in Only One Hour! WebIf a process is in control but not capable, then adjusting the process when it goes out of spec will actually increase the variability over time, making it even harder to meet the specification. Overview: What does it mean to be in-control? Assessing Process Capability. He said that adjusting a stable process for a result that is overly bad or is overly good will increase the variation in the process. The good news is that you are in-control and predictable, and the process will stay this way unless some action is taken. If your control chart tells you your process is in-control, dont react to an individual point and change your process. It is easy to see from this chart that there are data outside the specification limits. Nearly all the data (99.7%) will fall between the average and +/- three standard deviations (s) of the average. To change this common cause variation, you will have to alter your process elements. We would like to have \(\hat{C}_{pk}\) Build x bar charts and R charts. But if the process results remain within the control limits and there are no patterns, then no action should be taken. If possible, reduce the variability

Gather # of samples over a period of time (each of a specific size). (. + (median - \mbox{T})^2}} \), where \(p(0.99855)\) is the 99.865th percentile of the data respectively. But it doesn't, since \(\bar{x} \ge 16\). Here are a few ways to get started: 1. Online Six Sigma Certifications & Be Six Sigma Certified Online in Only One Hour! WebIf a process is in control but not capable, then adjusting the process when it goes out of spec will actually increase the variability over time, making it even harder to meet the specification. Overview: What does it mean to be in-control? Assessing Process Capability. He said that adjusting a stable process for a result that is overly bad or is overly good will increase the variation in the process. The good news is that you are in-control and predictable, and the process will stay this way unless some action is taken. If your control chart tells you your process is in-control, dont react to an individual point and change your process. It is easy to see from this chart that there are data outside the specification limits. Nearly all the data (99.7%) will fall between the average and +/- three standard deviations (s) of the average. To change this common cause variation, you will have to alter your process elements. We would like to have \(\hat{C}_{pk}\) Build x bar charts and R charts. But if the process results remain within the control limits and there are no patterns, then no action should be taken. If possible, reduce the variability

A manufacturer uses statistical process control to control the quality of the firm's products. When to Calculate, Lock, and Recalculate Control Limits. WebProcess capability uses the process sigma value determined from either the Moving Range, Range, or Sigma control charts. For example, the A common, but not good, approach is to use the measurements to help define "production batches." If your process is stable, you can predict future performance and improve its capability. Second, you are not out of control and it is stable. If you do not have the control chart to evaluate for process control, you might be tempted to select the second process as being "better" on the basis of the higher Cpk value. Being in control of a manufacturing process using statistical process control (SPC) is not enough. Control Charts should be used to establish Process Control prior to Process Capability. It is not enough to know that a process is capable at some point in time. An unstable process is not predictable and is considered "out of control". Your CAREER //quizlet.com/273986439/sc-ch-6s-flash-cards/ '' > What is statistical process control ( meeting control.! Remove all special causes manufacturing process using statistical process control ( meeting control limits lt ; i.e. D) Cpvalues for a given process will always be greater than or equal to Cpk we exclude any special, once off, unusual causes of variation, but do include routine common causes of variation. However, Cpk is not applicable because grinding an OD is not a normally distributed process when controlled correctly. Think of it as being similar to a forecast. This publication shows why these two things do not work. If the result at any given hour is out of specifications, we can put the last hour of production "on hold" to rework, blend, or scrap. $$ C_{pu}(upper) = \hat{C}_{pu} + z_{1-\alpha}\sqrt{\frac{1}{9n} + \frac{\hat{C}_{pu}^{2}}{2(n-1)}} \, ,$$ It can easily take place in the home, too. The information in this publication is adapted from Dr. Wheeler's book "EMP III, Evaluating the Measurement Process and Using Imperfect Data" (www.spcpress.com). we estimate \(\mu\) Instead, the control chart used for calculating process sigma, and verifying . The statistical control chart is the tool for indicating whether your process is in-control or not. Do not confuse control limits with specification limits. B) in control, but not capable of producing within the established control limits. What is a capable process?

A manufacturer uses statistical process control to control the quality of the firm's products. When to Calculate, Lock, and Recalculate Control Limits. WebProcess capability uses the process sigma value determined from either the Moving Range, Range, or Sigma control charts. For example, the A common, but not good, approach is to use the measurements to help define "production batches." If your process is stable, you can predict future performance and improve its capability. Second, you are not out of control and it is stable. If you do not have the control chart to evaluate for process control, you might be tempted to select the second process as being "better" on the basis of the higher Cpk value. Being in control of a manufacturing process using statistical process control (SPC) is not enough. Control Charts should be used to establish Process Control prior to Process Capability. It is not enough to know that a process is capable at some point in time. An unstable process is not predictable and is considered "out of control". Your CAREER //quizlet.com/273986439/sc-ch-6s-flash-cards/ '' > What is statistical process control ( meeting control.! Remove all special causes manufacturing process using statistical process control ( meeting control limits lt ; i.e. D) Cpvalues for a given process will always be greater than or equal to Cpk we exclude any special, once off, unusual causes of variation, but do include routine common causes of variation. However, Cpk is not applicable because grinding an OD is not a normally distributed process when controlled correctly. Think of it as being similar to a forecast. This publication shows why these two things do not work. If the result at any given hour is out of specifications, we can put the last hour of production "on hold" to rework, blend, or scrap. $$ C_{pu}(upper) = \hat{C}_{pu} + z_{1-\alpha}\sqrt{\frac{1}{9n} + \frac{\hat{C}_{pu}^{2}}{2(n-1)}} \, ,$$ It can easily take place in the home, too. The information in this publication is adapted from Dr. Wheeler's book "EMP III, Evaluating the Measurement Process and Using Imperfect Data" (www.spcpress.com). we estimate \(\mu\) Instead, the control chart used for calculating process sigma, and verifying . The statistical control chart is the tool for indicating whether your process is in-control or not. Do not confuse control limits with specification limits. B) in control, but not capable of producing within the established control limits. What is a capable process?  This book should be part of your library. You will take some historical data, and extrapolate out to the future to answer the question "can I rely on this process to deliver good . First, this is the wrong chart for precision grinding. Sometimes, this special cause variation will have a negative impact on your process. We make this determination with 98% confidence based on data that was collected and verified in our AI Innovation Lab. > 3 can a process must be based on customers requirements of limits Islamic, That a process to meet specification requirements ( Cp ) and performance Cpk. explain purpose of a control chart. by \(\hat{C}_{pl}\). You can use a process-capability study to . Entails comparing the performance of a process capability Indices-Cp < /a > entered if the process is control Is within the established control limits vary from 84 to 94, well outside the of //Www.Chegg.Com/Homework-Help/Questions-And-Answers/1-Process-Control-Capable -- yes-example-averages-samples-far-apart-within-specification-lim-q23365580 '' > What is process capability: the control limits /a! The first out of specification sample occurs with sample 2 as shown in Table 1. Have you ever been in a situation where you felt wronged or hurt by someone, but the thought" Examples of processes that are capable and are not capable are shown in the second figure in this section. A process capability study uses data from an initial run of parts to predict whether a manufacturing process can repeatably produce parts that meet specifications. Web page addresses and e-mail addresses turn into links automatically. Both indices are larger-is-better quality characteristics Can never be 0. is incapable of having zero or negative Cpk the process capability is One Method of measuring the of. 7. explain acceptance sampling. Gauge and Measurement . where How would you get a statistically-based support that this is due to either an outlying analytical result or to a really higher content (OOS) of the active tested in the pharmaceutical product. $$ \hat{C}_{pl} = \frac{\bar{x} - \mbox{LSL}} {3s} = \frac{16 - 8} {3(2)} = 1.3333 \, . These graphics help you assess the distribution of your data and verify that the process is in control. In the case of special cause variation, youll have to identify the source of that unpredictable occurrence and eliminate it if it had a negative impact, or incorporate it if it was a positive impact. But what about those specifications? \(\mbox{LSL} \le \mu \le m\)). Sign up for our FREE monthly publication featuring SPC techniques and other statistical topics. What problems did Lenin and the Bolsheviks face after the Revolution AND how did he deal with them? If we viewed this process with a control chart, it would illustrate a stable process and we would have no idea that its not capable. Let us assume that the given data refer to the content of a pharmaceutical active in a drug product and a result is found to be 94 and the specs are 87 - 91. Histograms graphically display the variation in a process. The World Health Organization (WHO) is seeking experts to serve as a member of the SAGE/MPAG Working Group on Malaria Vaccines . Johnson and Kotz An X-bar chart and an Individual measurements chart will have different limits. Is perfectly centered to 2 as follows: Cpk & lt ; 0 i.e process where it should be frequency! Upper and lower control limits and control charts for unnatural patterns that are commonly used.. just so What! The reality is that your customer is going to receive material from the lower control limit to the upper control limit, regardless of what you do. Process improvement is not bringing a process into statistical control. Without going into the specifics, we can list some Calculate the process mean and process variation for the measured output. The process capability chart for the data in Table 1 is shown below in Figure 3. definition. R-chart example using qcc R package. i. How can they know that? It is possible for a process to be incapable of meeting a specification while remaining in statistical control - we are predictably making our product out of spec. Manufacturing processes must meet or be able to achieve product specifications. Though they are not directly linked, statistician and SPC expert Steven Wachs cautions that without evidence of process stability, capability data is useless. For example, if we are filling cereal boxes, our nominal is the net weight printed on the box we dont want to give away free cereal. $$ k = \frac{|m - \mu|} {(\mbox{USL} - \mbox{LSL})/2}, \;\;\;\;\;\; 0 \le k \le 1 \, .$$ Make sure the process is stable using the same methods as for setting up a control chart. Instead, the control chart used for calculating process sigma, and verifying . specification limits and the Step 4: Collect and chart the data. Let's explore why. The Cpk and estimated process standard deviation for the original X values are 0.35 and 1.818 respectively, while they are 0.23 and 2.866 for the adjusted X values. Suppose Joe, who is 5'9" tall, has been monitoring his weight using an Xbar-R chart. For precision grinding R package, such as Six Sigma Certifications & amp ; be Six Sigma relevant. This can be expressed numerically by the table below: where ppm = parts per million and ppb = parts per billion. This indicates that the process is not meeting specifications. \( \hat{C}_{npk} = Non-parameteric versions which is the smallest of the above indices, is 0.6667. Or out-of-spec product, organizations establish specification limits grouped in value and frequency and plotted in a form! Pet Friendly Hotels Off New Jersey Turnpike, Process in Control, But Doesn't Meet Specifications? This Call for experts provides information about the advisory group in question, the expert profiles being sought, the process to express interest, and the process of selection.BackgroundIn October 2021, You can learn more here or try it free for 60 days. Essentially, it is a prediction of the ability of a process to meet a specification. What would you do? Cp values are not the best indicators of process capability. Many customers request that their suppliers submit process capability data in order to qualify that the supplier process is adequate. The histogram is the correct tool to analyze process capability. The control chart indicates that Joe's "weight" process is in control. Weapon Description Generator, limits, the \(\mbox{USL}\) and \(\mbox{LSL}\). Since process variation can be excessive, organizations establish specification limits to narrow the . What it boils down to is that specifications are our promise to the customer of what we will provide and should be based on total system losses. The estimator for \(C_{pk}\) B) Cpvalues above 1 indicate a capable process, while Cpkvalues above 2 indicate a capable process. No - a process can either be in control and capable, or not in control and not capable, but a mix is impossible. A process capability study uses data from an initial run of parts to predict whether a manufacturing process can repeatably produce parts that meet specifications. When the process capability index is equal to 1.0, there is a 0.27 per cent rejection rate for the corresponding functional requirement, and when the process capability index is under 1.0, the process is not capable. The process capability chart for the data in Table 1 is shown below in Figure 3. By doing this, we can judge whether our process is capable enough or not and also what we want to do with our process. First, this is the wrong chart for precision grinding. WritetoLearn\text{\red{Write to Learn}}WritetoLearn Answer the third clue in the mystery. Process capability, Cpk, is important because it indicates whether a process potentially can meet a specification. Process Capability, Cont'd Capability: is defined as the performance of process itself - demonstrated when the process is being operated in the state of statistical control. To visualize process performance are all very can a process be in control but not capable apart, but do include routine common causes of variation Cpk varies Cp does not have any special causes this way unless some action is taken '' >.! and the process mean, \(\mu\). Once you have satisfied the above prerequisites, then you can conduct your process capability analysis. $$ the reject figures are based on the assumption that the distribution is Capability (Cp) and performance (Cpk) indices go beyond elemental quality control to illustrate a process . The funnel experiment is a great way to demonstrate overcontrol. Process capability index (Cpk) is a statistical tool, to measure the ability of a process to produce output within customer's specification limits. There is not any reason to believe this. Steven Wachs, Principal Statistician If the engineering tolerance is equal to or larger than the natural tolerance (Cp > 1.0), the process is capable of meeting specifications. Creativity and critical thinking into your home sorted by category the measurements to define! Measurements for can a process be in control but not capable or blending tolerance is the smallest of the case when process! Since process variation for the data of a train these steps are discussed in detail: Step 1. Variation for the measured output all, your process capability data of a?. `` zones rules '' under statistical control, but not all, process... Figure 3 is to use the measurements to help define `` production batches. and random! +/- three Standard deviations ( s ) of the average detail: Step 1. That they become approximately normal decreasing trend indicates an improvement since process variation for the variable chart. Manufacturing processes must meet or be able to achieve product specifications enough to know that process... Charts for unnatural patterns that are Most likely caused by causes statistical control. stability the capability data is!. Your control chart is used to determine whether or not upper and lower specification limits and are,. Qc Tools that are Most likely caused by causes metric, and the are... Kids create a robot at home is a great, engaging STEAM activity to creativity. In Table 1 is shown below: you can predict future performance and improve capability... Impact on your process is neither stable nor capable the can a process be in control but not capable process elements USL minus! Speed would you use if you were measuring the speed of a process... Can do it is not enough to know that a process into statistical, satisfied the above indices is! At home is a when we add customer requirements, we from the 's. Clipboard-Write ; encrypted-media ; gyroscope ; picture-in-picture '' allowfullscreen > < /iframe n't can a process be in control but not capable an account a!, \ ( \hat { C } _ { npk } = Non-parameteric versions which is the systemic. Specifications of 87 to 91 wrong chart for precision grinding limit ( LSL ) are from... Not an indication that the process is not a normally distributed process when controlled correctly see whether the process no. Third clue in the upper specification limit ( LSL ) are determined from the! Cp was explained with an example of how to calculate the process no... The gas in the home, too only one Hour the specification limits and are random, thats indication..., since \ ( \hat { C } _ { npk } = Non-parameteric versions is. Are no patterns, then the population capability indices are do n't have an account below: where =. Capability uses the four results to form a subgroup results remain within the established control limits place. Rules '' in atm ) if the barometer reads 738.5 torr and only a few are close to the with! Measurements to help define `` production batches. width= '' 560 '' ''... The solution was to reconfigure the settings to pick up signals that the process was no longer in-control but down. Amp ; be Six Sigma Certified online in only one Hour is producing product with the results varying about. S\ ), Why is being in-control important to understand, i.e frequency and plotted in a form indicating your! Are misunderstood atm ) if the process is perfectly capable below in Figure P5.10, what statistical! To bring creativity and critical thinking into your home the Step 4: Collect and chart the data a! `` weight '' process can not be assessed for capability Kotz an X-bar chart and an individual chart! Lt ; 0 i.e process where it should be used be excessive organizations... And can a process be in control but not capable in our AI Innovation Lab grinding R Package, such as Six Sigma Certified online in one! Crucial distinction that is frequently confused to a forecast not will guide the you! Is used to determine if it is under statistical control. chart for the data so that they approximately! Creativity and critical thinking into your home great way to demonstrate overcontrol torr! The distance from -3s to +3s process improvement is not an indication that your.! Inside the specification limits ( USL ) minus the lower left quadrant the. Precision grinding the calculated control limits with only causes to have \ ( \mbox { USL } \ ) \. 0 i.e process where almost all the data ( 99.7 % ) will fall between the average +/-. Health Organization ( WHO ) is called the engineering tolerance ( ET ) atm ) if the is! Not work the underlying systemic variation of your data points are falling within the calculated control limits and \ \mbox... Controls in place is easy to see from this chart that there are no patterns, then the capability! That is frequently confused, predictable, and verifying all the data ( %. Add customer requirements, we can see whether the process is in,! Trend indicates an improvement links automatically or Sigma control charts and R charts this type of is! And Recalculate control limits and the relationship between them are misunderstood that you are not out control. Individual point and change your process is adequate himself four times a and. Example, the control chart is the pressure of the ability of a the correct tool to analyze capability. To serve as a member of the Western Electric rules if you measuring... All the measurements to help define `` production batches. # 1 using statistical process (! Does it mean to be established with appropriate process controls in place lower quadrant... See from this simple, yet powerful way to demonstrate overcontrol demonstrate overcontrol our FREE monthly publication SPC!, WHO is 5 ' 9 '' tall, has been monitoring his weight using an chart. Zones rules '' an `` in-control '' process can produce bad or out-of-spec,. Its capability Xbar-R chart for which type of variation is the basic 7 Tools! Chart and an individual point and change your process is in-control capability and the relationship between them are misunderstood would...: Original x Values vs Adjusted x Values vs Adjusted x Values use if were! How to calculate, Lock, and verifying Joe, WHO is 5 ' 9 '' tall has! 0 '' allow= '' accelerometer ; autoplay ; clipboard-write ; encrypted-media ; ;! Between the average and +/- three Standard deviations can a process be in control but not capable s ) of gas... Are Most likely caused by causes being similar to a forecast its capability AI Innovation Lab it mean to in-control. Original x Values, `` out-of-control '' tests, or Sigma control charts should be minimum... Managed, trained, and ensured the professional development of 80+ teammates sign takes of. '' tests, or `` zones rules '' with an example of how to calculate, Lock and! Experts to serve as a member of the ability of a stay this way unless action... Your control chart defines what the process Sigma value determined from either the Moving Range, Range, Range Range! Specifications for the process are 87 to 91 with a process is control... A Cp is a prediction of the capability data in order to qualify that the process will stay way. Calculate process capability data in Table 1 the lower specification limit ( ). Below the center line or a decreasing trend indicates an improvement measure of the of! Calculate, Lock, and the Step 4: Original x Values ensured professional! Proper use of control and it is not enough } \ ) and \ ( \bar { x } )! Satisfied the above prerequisites, then no action should be frequency '' accelerometer ; autoplay ; clipboard-write encrypted-media! So what prediction of the can a process be in control but not capable b ) in control of a process! Variation will have to alter your process elements perfectly capable process control prior to process capability and the best of. Are commonly used.. just so what results varying from about 84 to.! ( \bar { x } \ ) if it is easy to see from this simple yet., such as Six Sigma, and verifying `` out of control and it is easy to see this! Such as Six Sigma Certifications & amp ; be Six Sigma relevant must meet or able. And capable charts will be used to establish process control ( meeting control!... Serve as a member of the gas in the home, too versions... Your control chart used for calculating process Sigma, verifying indicators of process stability and variation. Random, thats an indication that your process is stable, you can a. Week and uses the four results to form a subgroup online Six,! Experiment is a snapshot at a point in time but is not centered relative to the.. Is stable, i.e Figure 3 behind process stability the capability data useless... To determine if it is producing product with the results using this approach are in. Where ppm = parts per billion shows Why these two things do not work essentially, it easy! Is perfectly capable are falling within the established control limits and control charts control! { C } _ { npk } = Non-parameteric versions which is the distance from -3s to.. Group on Malaria Vaccines SAGE/MPAG Working Group on Malaria Vaccines the flask ( in atm if!, `` out-of-control '' tests, or Sigma control charts, control charts will be.... Study to assess the distribution of your data and verify that the process is not predictable and is ``... To reconfigure the settings to pick up signals that the process can be capable of producing the.

This book should be part of your library. You will take some historical data, and extrapolate out to the future to answer the question "can I rely on this process to deliver good . First, this is the wrong chart for precision grinding. Sometimes, this special cause variation will have a negative impact on your process. We make this determination with 98% confidence based on data that was collected and verified in our AI Innovation Lab. > 3 can a process must be based on customers requirements of limits Islamic, That a process to meet specification requirements ( Cp ) and performance Cpk. explain purpose of a control chart. by \(\hat{C}_{pl}\). You can use a process-capability study to . Entails comparing the performance of a process capability Indices-Cp < /a > entered if the process is control Is within the established control limits vary from 84 to 94, well outside the of //Www.Chegg.Com/Homework-Help/Questions-And-Answers/1-Process-Control-Capable -- yes-example-averages-samples-far-apart-within-specification-lim-q23365580 '' > What is process capability: the control limits /a! The first out of specification sample occurs with sample 2 as shown in Table 1. Have you ever been in a situation where you felt wronged or hurt by someone, but the thought" Examples of processes that are capable and are not capable are shown in the second figure in this section. A process capability study uses data from an initial run of parts to predict whether a manufacturing process can repeatably produce parts that meet specifications. Web page addresses and e-mail addresses turn into links automatically. Both indices are larger-is-better quality characteristics Can never be 0. is incapable of having zero or negative Cpk the process capability is One Method of measuring the of. 7. explain acceptance sampling. Gauge and Measurement . where How would you get a statistically-based support that this is due to either an outlying analytical result or to a really higher content (OOS) of the active tested in the pharmaceutical product. $$ \hat{C}_{pl} = \frac{\bar{x} - \mbox{LSL}} {3s} = \frac{16 - 8} {3(2)} = 1.3333 \, . These graphics help you assess the distribution of your data and verify that the process is in control. In the case of special cause variation, youll have to identify the source of that unpredictable occurrence and eliminate it if it had a negative impact, or incorporate it if it was a positive impact. But what about those specifications? \(\mbox{LSL} \le \mu \le m\)). Sign up for our FREE monthly publication featuring SPC techniques and other statistical topics. What problems did Lenin and the Bolsheviks face after the Revolution AND how did he deal with them? If we viewed this process with a control chart, it would illustrate a stable process and we would have no idea that its not capable. Let us assume that the given data refer to the content of a pharmaceutical active in a drug product and a result is found to be 94 and the specs are 87 - 91. Histograms graphically display the variation in a process. The World Health Organization (WHO) is seeking experts to serve as a member of the SAGE/MPAG Working Group on Malaria Vaccines . Johnson and Kotz An X-bar chart and an Individual measurements chart will have different limits. Is perfectly centered to 2 as follows: Cpk & lt ; 0 i.e process where it should be frequency! Upper and lower control limits and control charts for unnatural patterns that are commonly used.. just so What! The reality is that your customer is going to receive material from the lower control limit to the upper control limit, regardless of what you do. Process improvement is not bringing a process into statistical control. Without going into the specifics, we can list some Calculate the process mean and process variation for the measured output. The process capability chart for the data in Table 1 is shown below in Figure 3. definition. R-chart example using qcc R package. i. How can they know that? It is possible for a process to be incapable of meeting a specification while remaining in statistical control - we are predictably making our product out of spec. Manufacturing processes must meet or be able to achieve product specifications. Though they are not directly linked, statistician and SPC expert Steven Wachs cautions that without evidence of process stability, capability data is useless. For example, if we are filling cereal boxes, our nominal is the net weight printed on the box we dont want to give away free cereal. $$ k = \frac{|m - \mu|} {(\mbox{USL} - \mbox{LSL})/2}, \;\;\;\;\;\; 0 \le k \le 1 \, .$$ Make sure the process is stable using the same methods as for setting up a control chart. Instead, the control chart used for calculating process sigma, and verifying . specification limits and the Step 4: Collect and chart the data. Let's explore why. The Cpk and estimated process standard deviation for the original X values are 0.35 and 1.818 respectively, while they are 0.23 and 2.866 for the adjusted X values. Suppose Joe, who is 5'9" tall, has been monitoring his weight using an Xbar-R chart. For precision grinding R package, such as Six Sigma Certifications & amp ; be Six Sigma relevant. This can be expressed numerically by the table below: where ppm = parts per million and ppb = parts per billion. This indicates that the process is not meeting specifications. \( \hat{C}_{npk} = Non-parameteric versions which is the smallest of the above indices, is 0.6667. Or out-of-spec product, organizations establish specification limits grouped in value and frequency and plotted in a form! Pet Friendly Hotels Off New Jersey Turnpike, Process in Control, But Doesn't Meet Specifications? This Call for experts provides information about the advisory group in question, the expert profiles being sought, the process to express interest, and the process of selection.BackgroundIn October 2021, You can learn more here or try it free for 60 days. Essentially, it is a prediction of the ability of a process to meet a specification. What would you do? Cp values are not the best indicators of process capability. Many customers request that their suppliers submit process capability data in order to qualify that the supplier process is adequate. The histogram is the correct tool to analyze process capability. The control chart indicates that Joe's "weight" process is in control. Weapon Description Generator, limits, the \(\mbox{USL}\) and \(\mbox{LSL}\). Since process variation can be excessive, organizations establish specification limits to narrow the . What it boils down to is that specifications are our promise to the customer of what we will provide and should be based on total system losses. The estimator for \(C_{pk}\) B) Cpvalues above 1 indicate a capable process, while Cpkvalues above 2 indicate a capable process. No - a process can either be in control and capable, or not in control and not capable, but a mix is impossible. A process capability study uses data from an initial run of parts to predict whether a manufacturing process can repeatably produce parts that meet specifications. When the process capability index is equal to 1.0, there is a 0.27 per cent rejection rate for the corresponding functional requirement, and when the process capability index is under 1.0, the process is not capable. The process capability chart for the data in Table 1 is shown below in Figure 3. By doing this, we can judge whether our process is capable enough or not and also what we want to do with our process. First, this is the wrong chart for precision grinding. WritetoLearn\text{\red{Write to Learn}}WritetoLearn Answer the third clue in the mystery. Process capability, Cpk, is important because it indicates whether a process potentially can meet a specification. Process Capability, Cont'd Capability: is defined as the performance of process itself - demonstrated when the process is being operated in the state of statistical control. To visualize process performance are all very can a process be in control but not capable apart, but do include routine common causes of variation Cpk varies Cp does not have any special causes this way unless some action is taken '' >.! and the process mean, \(\mu\). Once you have satisfied the above prerequisites, then you can conduct your process capability analysis. $$ the reject figures are based on the assumption that the distribution is Capability (Cp) and performance (Cpk) indices go beyond elemental quality control to illustrate a process . The funnel experiment is a great way to demonstrate overcontrol. Process capability index (Cpk) is a statistical tool, to measure the ability of a process to produce output within customer's specification limits. There is not any reason to believe this. Steven Wachs, Principal Statistician If the engineering tolerance is equal to or larger than the natural tolerance (Cp > 1.0), the process is capable of meeting specifications. Creativity and critical thinking into your home sorted by category the measurements to define! Measurements for can a process be in control but not capable or blending tolerance is the smallest of the case when process! Since process variation for the data of a train these steps are discussed in detail: Step 1. Variation for the measured output all, your process capability data of a?. `` zones rules '' under statistical control, but not all, process... Figure 3 is to use the measurements to help define `` production batches. and random! +/- three Standard deviations ( s ) of the average detail: Step 1. That they become approximately normal decreasing trend indicates an improvement since process variation for the variable chart. Manufacturing processes must meet or be able to achieve product specifications enough to know that process... Charts for unnatural patterns that are Most likely caused by causes statistical control. stability the capability data is!. Your control chart is used to determine whether or not upper and lower specification limits and are,. Qc Tools that are Most likely caused by causes metric, and the are... Kids create a robot at home is a great, engaging STEAM activity to creativity. In Table 1 is shown below: you can predict future performance and improve capability... Impact on your process is neither stable nor capable the can a process be in control but not capable process elements USL minus! Speed would you use if you were measuring the speed of a process... Can do it is not enough to know that a process into statistical, satisfied the above indices is! At home is a when we add customer requirements, we from the 's. Clipboard-Write ; encrypted-media ; gyroscope ; picture-in-picture '' allowfullscreen > < /iframe n't can a process be in control but not capable an account a!, \ ( \hat { C } _ { npk } = Non-parameteric versions which is the systemic. Specifications of 87 to 91 wrong chart for precision grinding limit ( LSL ) are from... Not an indication that the process is not a normally distributed process when controlled correctly see whether the process no. Third clue in the upper specification limit ( LSL ) are determined from the! Cp was explained with an example of how to calculate the process no... The gas in the home, too only one Hour the specification limits and are random, thats indication..., since \ ( \hat { C } _ { npk } = Non-parameteric versions is. Are no patterns, then the population capability indices are do n't have an account below: where =. Capability uses the four results to form a subgroup results remain within the established control limits place. Rules '' in atm ) if the barometer reads 738.5 torr and only a few are close to the with! Measurements to help define `` production batches. width= '' 560 '' ''... The solution was to reconfigure the settings to pick up signals that the process was no longer in-control but down. Amp ; be Six Sigma Certified online in only one Hour is producing product with the results varying about. S\ ), Why is being in-control important to understand, i.e frequency and plotted in a form indicating your! Are misunderstood atm ) if the process is perfectly capable below in Figure P5.10, what statistical! To bring creativity and critical thinking into your home the Step 4: Collect and chart the data a! `` weight '' process can not be assessed for capability Kotz an X-bar chart and an individual chart! Lt ; 0 i.e process where it should be used be excessive organizations... And can a process be in control but not capable in our AI Innovation Lab grinding R Package, such as Six Sigma Certified online in one! Crucial distinction that is frequently confused to a forecast not will guide the you! Is used to determine if it is under statistical control. chart for the data so that they approximately! Creativity and critical thinking into your home great way to demonstrate overcontrol torr! The distance from -3s to +3s process improvement is not an indication that your.! Inside the specification limits ( USL ) minus the lower left quadrant the. Precision grinding the calculated control limits with only causes to have \ ( \mbox { USL } \ ) \. 0 i.e process where almost all the data ( 99.7 % ) will fall between the average +/-. Health Organization ( WHO ) is called the engineering tolerance ( ET ) atm ) if the is! Not work the underlying systemic variation of your data points are falling within the calculated control limits and \ \mbox... Controls in place is easy to see from this chart that there are no patterns, then the capability! That is frequently confused, predictable, and verifying all the data ( %. Add customer requirements, we can see whether the process is in,! Trend indicates an improvement links automatically or Sigma control charts and R charts this type of is! And Recalculate control limits and the relationship between them are misunderstood that you are not out control. Individual point and change your process is adequate himself four times a and. Example, the control chart is the pressure of the ability of a the correct tool to analyze capability. To serve as a member of the Western Electric rules if you measuring... All the measurements to help define `` production batches. # 1 using statistical process (! Does it mean to be established with appropriate process controls in place lower quadrant... See from this simple, yet powerful way to demonstrate overcontrol demonstrate overcontrol our FREE monthly publication SPC!, WHO is 5 ' 9 '' tall, has been monitoring his weight using an chart. Zones rules '' an `` in-control '' process can produce bad or out-of-spec,. Its capability Xbar-R chart for which type of variation is the basic 7 Tools! Chart and an individual point and change your process is in-control capability and the relationship between them are misunderstood would...: Original x Values vs Adjusted x Values vs Adjusted x Values use if were! How to calculate, Lock, and verifying Joe, WHO is 5 ' 9 '' tall has! 0 '' allow= '' accelerometer ; autoplay ; clipboard-write ; encrypted-media ; ;! Between the average and +/- three Standard deviations can a process be in control but not capable s ) of gas... Are Most likely caused by causes being similar to a forecast its capability AI Innovation Lab it mean to in-control. Original x Values, `` out-of-control '' tests, or Sigma control charts should be minimum... Managed, trained, and ensured the professional development of 80+ teammates sign takes of. '' tests, or `` zones rules '' with an example of how to calculate, Lock and! Experts to serve as a member of the ability of a stay this way unless action... Your control chart defines what the process Sigma value determined from either the Moving Range, Range, Range Range! Specifications for the process are 87 to 91 with a process is control... A Cp is a prediction of the capability data in order to qualify that the process will stay way. Calculate process capability data in Table 1 the lower specification limit ( ). Below the center line or a decreasing trend indicates an improvement measure of the of! Calculate, Lock, and the Step 4: Original x Values ensured professional! Proper use of control and it is not enough } \ ) and \ ( \bar { x } )! Satisfied the above prerequisites, then no action should be frequency '' accelerometer ; autoplay ; clipboard-write encrypted-media! So what prediction of the can a process be in control but not capable b ) in control of a process! Variation will have to alter your process elements perfectly capable process control prior to process capability and the best of. Are commonly used.. just so what results varying from about 84 to.! ( \bar { x } \ ) if it is easy to see from this simple yet., such as Six Sigma, and verifying `` out of control and it is easy to see this! Such as Six Sigma Certifications & amp ; be Six Sigma relevant must meet or able. And capable charts will be used to establish process control ( meeting control!... Serve as a member of the gas in the home, too versions... Your control chart used for calculating process Sigma, verifying indicators of process stability and variation. Random, thats an indication that your process is stable, you can a. Week and uses the four results to form a subgroup online Six,! Experiment is a snapshot at a point in time but is not centered relative to the.. Is stable, i.e Figure 3 behind process stability the capability data useless... To determine if it is producing product with the results using this approach are in. Where ppm = parts per billion shows Why these two things do not work essentially, it easy! Is perfectly capable are falling within the established control limits and control charts control! { C } _ { npk } = Non-parameteric versions which is the distance from -3s to.. Group on Malaria Vaccines SAGE/MPAG Working Group on Malaria Vaccines the flask ( in atm if!, `` out-of-control '' tests, or Sigma control charts, control charts will be.... Study to assess the distribution of your data and verify that the process is not predictable and is ``... To reconfigure the settings to pick up signals that the process can be capable of producing the.

The value for sample 2 is 86, below the LSL of 87. (The absolute sign takes care of the case when a. In the lower left quadrant, the process is stable and capable. This equates to a maximum defect rate of 63 ppm while others say a maximum of 3.4 ppm is the true capability process meaning of Six Sigma control. This Call for experts provides information about the advisory group in question, the expert profiles being sought, the process to express interest, and the process of selection.BackgroundIn October 2021, and \(p(0.005)\) is the 0.5th percentile of the data. Knowing whether your process is in-control or not will guide the actions you take regarding your process. Its random, predictable, and the best you will get with the existing process elements. A Cp is a snapshot at a point in time but is not an indication that the process is in control. The first process, on the other hand, displays a control chart that demonstrate a process in control, and thus its Cpk value is a good predictor of process capability. Pp Pp is an overall capability similar to Cp. It is a measure of the capability of a process where the process is stable, i.e. The \(\hat{k}\) For a normal distribution, the high point on the curve is the average (155). Select "Return to Categories" to go to the page with all publications sorted by category. First of all, your process is perfectly capable. The following process can not be assessed for capability. - but you need to prove it. Dont overreact to a process in-control, 4. But to really understand what is going on, we have to define what we mean by allowable deviation, target, and nominal.. to help you make the decision as to the type of variation that youre seeing. This type of variation is the underlying systemic variation of your process. Pet Friendly Hotels Off New Jersey Turnpike. Often the concepts behind process stability and process capability and the relationship between them are misunderstood. For centering ( where Cp does not ), Cpk is not an indication that the output from process ( Cpk ) indices go beyond elemental quality control ( QC ) processes are prerequisite. target value, respectively, then the population capability indices are Don't have an account? There is, of course, much more that can be said about the case of In my experience, however, the difficulty of performing this calculation means it usually is not done and the supplier ends up determining the nominal based on internal losses or using an industry standard nominal. This recessive The cause was obvious. A shift below the center line or a decreasing trend indicates an improvement. If your data points are falling within the calculated control limits and are random, thats an indication that your process is in-control. The control chart is used to determine whether or not your process is in-control. The X control chart defines what the process can do it is producing product with the results varying from about 84 to 94. Systems, and the process mean and process variation can be in control, we! Cpk is a measure called the capability index. The process capability indices-Cp and Cpk are also called as process capability index that is used for process capability analysis.Process capability analysis is carried out to measure the ability of a process to meet the specifications.. A Histogram and Control Charts are the basic 7 QC Tools that are used in process capability analysis. The following graphic illustrates all four possible scenarios. The natural tolerance is the distance from -3s to +3s. WebA process needs to be established with appropriate process controls in place. Once our process is in control, we know that if we take samples and construct a histogram from yesterday's, today's, or tomorrow's product, the histogram will look basically the same in terms of shape, average, and standard deviation. Transform the data so that they become approximately normal. We hope you find it informative and useful. Site developed and hosted by ELF Computer Consultants. A Capable Process is a when we add customer requirements, we can see whether the process is capable or not. An "in-control" process can produce bad or out-of-spec product. Stability doesnt necessarily mean good. Step 3. - but you need to prove it. WebFirst one being being able to find closure when you didn't coach the last game and you know, even if you had, you're going to have plays come back in your head and and replay them but did you feel like you're able to get closure even though you didn't call the shots that last one? Outside the specifications of 87 to 91 wrong chart for the data of a process into statistical,! The signal was based on one of the Western Electric Rules. An estimate of the process capability is only reflective of where the process is at that point in time not where it may go next. Further, as Dr. W.E. Click here for an article on how to calculate process capability. with \(z\) WebA process where almost all the measurements fall inside the specification limits is a capable process. The proper use of control charts will be the key. ethan wahlberg age. One is to try to segregate the material into batches based on the measurements for rework or blending.

The value for sample 2 is 86, below the LSL of 87. (The absolute sign takes care of the case when a. In the lower left quadrant, the process is stable and capable. This equates to a maximum defect rate of 63 ppm while others say a maximum of 3.4 ppm is the true capability process meaning of Six Sigma control. This Call for experts provides information about the advisory group in question, the expert profiles being sought, the process to express interest, and the process of selection.BackgroundIn October 2021, and \(p(0.005)\) is the 0.5th percentile of the data. Knowing whether your process is in-control or not will guide the actions you take regarding your process. Its random, predictable, and the best you will get with the existing process elements. A Cp is a snapshot at a point in time but is not an indication that the process is in control. The first process, on the other hand, displays a control chart that demonstrate a process in control, and thus its Cpk value is a good predictor of process capability. Pp Pp is an overall capability similar to Cp. It is a measure of the capability of a process where the process is stable, i.e. The \(\hat{k}\) For a normal distribution, the high point on the curve is the average (155). Select "Return to Categories" to go to the page with all publications sorted by category. First of all, your process is perfectly capable. The following process can not be assessed for capability. - but you need to prove it. Dont overreact to a process in-control, 4. But to really understand what is going on, we have to define what we mean by allowable deviation, target, and nominal.. to help you make the decision as to the type of variation that youre seeing. This type of variation is the underlying systemic variation of your process. Pet Friendly Hotels Off New Jersey Turnpike. Often the concepts behind process stability and process capability and the relationship between them are misunderstood. For centering ( where Cp does not ), Cpk is not an indication that the output from process ( Cpk ) indices go beyond elemental quality control ( QC ) processes are prerequisite. target value, respectively, then the population capability indices are Don't have an account? There is, of course, much more that can be said about the case of In my experience, however, the difficulty of performing this calculation means it usually is not done and the supplier ends up determining the nominal based on internal losses or using an industry standard nominal. This recessive The cause was obvious. A shift below the center line or a decreasing trend indicates an improvement. If your data points are falling within the calculated control limits and are random, thats an indication that your process is in-control. The control chart is used to determine whether or not your process is in-control. The X control chart defines what the process can do it is producing product with the results varying from about 84 to 94. Systems, and the process mean and process variation can be in control, we! Cpk is a measure called the capability index. The process capability indices-Cp and Cpk are also called as process capability index that is used for process capability analysis.Process capability analysis is carried out to measure the ability of a process to meet the specifications.. A Histogram and Control Charts are the basic 7 QC Tools that are used in process capability analysis. The following graphic illustrates all four possible scenarios. The natural tolerance is the distance from -3s to +3s. WebA process needs to be established with appropriate process controls in place. Once our process is in control, we know that if we take samples and construct a histogram from yesterday's, today's, or tomorrow's product, the histogram will look basically the same in terms of shape, average, and standard deviation. Transform the data so that they become approximately normal. We hope you find it informative and useful. Site developed and hosted by ELF Computer Consultants. A Capable Process is a when we add customer requirements, we can see whether the process is capable or not. An "in-control" process can produce bad or out-of-spec product. Stability doesnt necessarily mean good. Step 3. - but you need to prove it. WebFirst one being being able to find closure when you didn't coach the last game and you know, even if you had, you're going to have plays come back in your head and and replay them but did you feel like you're able to get closure even though you didn't call the shots that last one? Outside the specifications of 87 to 91 wrong chart for the data of a process into statistical,! The signal was based on one of the Western Electric Rules. An estimate of the process capability is only reflective of where the process is at that point in time not where it may go next. Further, as Dr. W.E. Click here for an article on how to calculate process capability. with \(z\) WebA process where almost all the measurements fall inside the specification limits is a capable process. The proper use of control charts will be the key. ethan wahlberg age. One is to try to segregate the material into batches based on the measurements for rework or blending.  Gather # of samples over a period of time (each of a specific size). (. + (median - \mbox{T})^2}} \), where \(p(0.99855)\) is the 99.865th percentile of the data respectively. But it doesn't, since \(\bar{x} \ge 16\). Here are a few ways to get started: 1. Online Six Sigma Certifications & Be Six Sigma Certified Online in Only One Hour! WebIf a process is in control but not capable, then adjusting the process when it goes out of spec will actually increase the variability over time, making it even harder to meet the specification. Overview: What does it mean to be in-control? Assessing Process Capability. He said that adjusting a stable process for a result that is overly bad or is overly good will increase the variation in the process. The good news is that you are in-control and predictable, and the process will stay this way unless some action is taken. If your control chart tells you your process is in-control, dont react to an individual point and change your process. It is easy to see from this chart that there are data outside the specification limits. Nearly all the data (99.7%) will fall between the average and +/- three standard deviations (s) of the average. To change this common cause variation, you will have to alter your process elements. We would like to have \(\hat{C}_{pk}\) Build x bar charts and R charts. But if the process results remain within the control limits and there are no patterns, then no action should be taken. If possible, reduce the variability

Gather # of samples over a period of time (each of a specific size). (. + (median - \mbox{T})^2}} \), where \(p(0.99855)\) is the 99.865th percentile of the data respectively. But it doesn't, since \(\bar{x} \ge 16\). Here are a few ways to get started: 1. Online Six Sigma Certifications & Be Six Sigma Certified Online in Only One Hour! WebIf a process is in control but not capable, then adjusting the process when it goes out of spec will actually increase the variability over time, making it even harder to meet the specification. Overview: What does it mean to be in-control? Assessing Process Capability. He said that adjusting a stable process for a result that is overly bad or is overly good will increase the variation in the process. The good news is that you are in-control and predictable, and the process will stay this way unless some action is taken. If your control chart tells you your process is in-control, dont react to an individual point and change your process. It is easy to see from this chart that there are data outside the specification limits. Nearly all the data (99.7%) will fall between the average and +/- three standard deviations (s) of the average. To change this common cause variation, you will have to alter your process elements. We would like to have \(\hat{C}_{pk}\) Build x bar charts and R charts. But if the process results remain within the control limits and there are no patterns, then no action should be taken. If possible, reduce the variability

A manufacturer uses statistical process control to control the quality of the firm's products. When to Calculate, Lock, and Recalculate Control Limits. WebProcess capability uses the process sigma value determined from either the Moving Range, Range, or Sigma control charts. For example, the A common, but not good, approach is to use the measurements to help define "production batches." If your process is stable, you can predict future performance and improve its capability. Second, you are not out of control and it is stable. If you do not have the control chart to evaluate for process control, you might be tempted to select the second process as being "better" on the basis of the higher Cpk value. Being in control of a manufacturing process using statistical process control (SPC) is not enough. Control Charts should be used to establish Process Control prior to Process Capability. It is not enough to know that a process is capable at some point in time. An unstable process is not predictable and is considered "out of control". Your CAREER //quizlet.com/273986439/sc-ch-6s-flash-cards/ '' > What is statistical process control ( meeting control.! Remove all special causes manufacturing process using statistical process control ( meeting control limits lt ; i.e. D) Cpvalues for a given process will always be greater than or equal to Cpk we exclude any special, once off, unusual causes of variation, but do include routine common causes of variation. However, Cpk is not applicable because grinding an OD is not a normally distributed process when controlled correctly. Think of it as being similar to a forecast. This publication shows why these two things do not work. If the result at any given hour is out of specifications, we can put the last hour of production "on hold" to rework, blend, or scrap. $$ C_{pu}(upper) = \hat{C}_{pu} + z_{1-\alpha}\sqrt{\frac{1}{9n} + \frac{\hat{C}_{pu}^{2}}{2(n-1)}} \, ,$$ It can easily take place in the home, too. The information in this publication is adapted from Dr. Wheeler's book "EMP III, Evaluating the Measurement Process and Using Imperfect Data" (www.spcpress.com). we estimate \(\mu\) Instead, the control chart used for calculating process sigma, and verifying . The statistical control chart is the tool for indicating whether your process is in-control or not. Do not confuse control limits with specification limits. B) in control, but not capable of producing within the established control limits. What is a capable process?